Chapter-4

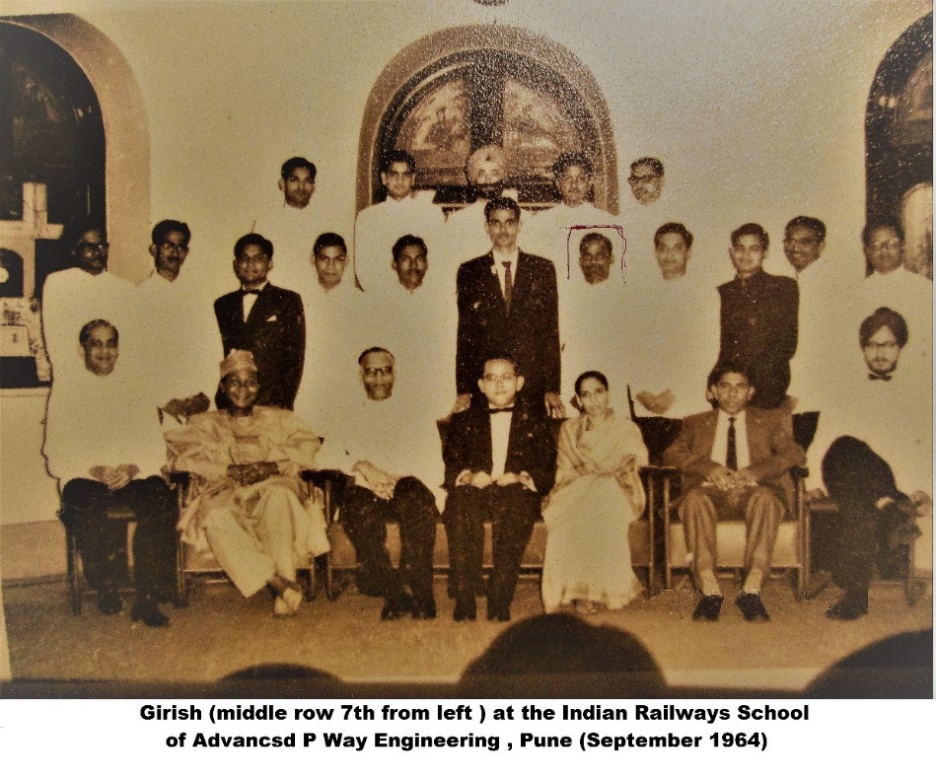

Training in Permanent Way Engineering at Poona.

This is how the track technology institution and the city were known during my training period from September 1964 to November 1964. The institution building located on the exit side of the station looks like an erstwhile colonial villa overshadowed by trees.

The building is brick-walled bearing on ornate columns. The roof is mangalore-tiled supported on wooden trusses. The curvilinear steps & the generous portico at the entrance with octagonal mangalore-tiled roof weaves charm to the visitors. The foreground is landscaped. The hostel was in a rented building “Sethna house” located somewhere opposite to Aga Khan palace, about 100 meters from the main road. The approach from the main road passed through thick clusters of trees resembling the scenes of the then popular movie “O kaun thi”. After finishing breakfast in the hostel mess, the bus of Poona road transport corporation took us to the institute at the station. Lunch was served there itself. After classes were over the bus would take us back to the hostel. Watching the overflowing water, while passing over the barrage on Mula river (near Bund garden) was a pleasant experience. There was no physical training or drill as at Baroda. However, we enjoyed playing badminton at the court next to our hostel or relaxing in the lounge.

Ours was a small batch of about 20 trainees including officers from Nigerian railway and Sri Lankan railway .Sri Hari Sinha was the Principal, Sri R.M.Ogle the Vice Principal and Sri L.H.J.Corner the AEN Instructor. Srivastava Ji was the technical assistant. We were given an insight into track technology aided by lectures, drawing classes and visit to the model room. There was a small layout of track also in the school premises for practical training.

The sleepers rest on ballast cushion which not only provides resilience but also facilitates correction of level and alignment of the track. Against popular belief the rails are not laid level but are canted 1 in 20 inward. To match the rail profile the wheels are also coned 1 in 20 outwards. This takes care of the horizontality of the axle. On a straight track this rail-wheel configuration ensures that the running wheels occupy the rails centrally and the flanges are prevented from striking the rail sides due to track irregularity. On curved track this permits the outer wheels to negotiate larger distance compared to the inner wheels thereby preventing slippage.

Sand humps or Snag dead ends- They consist of mounds of sand of specified dimension covering a length of upgradient track under it. They are provided on the loop lines and the points are set for it while receiving a train. If the incoming train overshoots in this process, it enters the sand hump and is thereby stopped due to combined resistance of sand hump and the rising grade without much damage to it. The running lines are thus prevented from being fouled. A discerning observer must have seen it when his train passing through loop line is about to enter the running line. Derailing switches are provided on a loop line or siding to ensure that a standing vehicle does not go beyond a particular point and if it accidently rolls it gets derailed at this device. Thus, isolation of the running line is safeguarded. Fouling Marks (F.M.) are provided in between converging lines at the point beyond which centre-to-centre distance of the tracks becomes less than the stipulated minimum dimension. The train must stand in the rear of F.M. so as to avoid side collision with a train moving on the adjacent converging line. Made of stone or cement concrete blocks or pieces of rails embedded in concrete so as to be difficult to dislodge, they measure 1500mm in length and painted white with the letters F.M. inscribed thereon so as to be distinctly visible. A regular train traveller will hardly miss them.

Grade compensation-To counteract the effect of curve resistance when a train is negotiating an upgradient on a curve the limiting gradient is reduced (compensated) to keep the overall train resistance within limit of the tractive power of the locomotive. Slip sidings are provided at stations located on steep grade to prevent the vehicles from entering the block section. Catch sidings are provided in a ghat section to prevent the vehicles entering the station section from the block section. Both these sidings are interlocked with block instruments.

Ghat section trolley- From Pune we arrived at Lonavala ,the higher end of the Karjat-Lonavala ghat section (a stretch with steep grades, sharp curves, high banks, deep cuttings, viaducts and tunnels) between Mumbai and Pune. Our destination was Karjat ,28 kms away and 568 metres below.

We set forth in a convoy of push trolleys manned by smart trolleymen. After covering some distance, the steep downgrade commenced. Here (near Monkey hill) a catch siding is provided to arrest runaway trains.

The points are normally set for the catch siding with the signal remaining in danger position. The driver of the train entering the section is required to prove adequacy of brake power by stopping the train short of the signal. Then only the points are set for the running line and the signal taken off. If the driver fails, his train enters the catch siding. The damage/loss in the event of a train entering the catch siding is insignificant compared to the disastrous consequence of a train losing control in the midsection. Here onward no pushing of the trolleys was required. On the other hand, the trolleymen were regularly applying hand brakes to keep the trolleys under control and ensure adequate headway with the adjacent trollies. Construction of series of tunnels, deep hard rock cuttings and colossal viaducts on lofty piers in an inhospitable terrain of the Bhor ghat incline some 100 years ago was a compelling narrative of accomplishment, suffering and even loss of lives.

Treasure hunt- The sprawling lawn of the Principal’s bungalow at Koregaon park provided an ideal setting for this interesting game, designed by the Principal’s daughter. Small groups were formed amongst us. To start with each group had to pick up a paper chit. By following the lead contained therein the group had to locate the second chit cleverly hidden in the cavity of the trunk or in between leaves. By correctly following the leads provided in successive chits one came across the treasure which turned out to be a basket & a broom.

Receiving premiere institutional training in Permanent Way Engineering in a comfortable and conducive learning environment was a fulfilling experience. I will always treasure the memories of my days at the Institute with its iconic British-era building, the lonesome hostel and our learned educators.

Comments of the Dy CE(G) on Poona training--After completion of the course I returned to the S.E.Rly Hqrs at Calcutta and reported to the Dy CE (G). He was keen to see my class notes. After going through them he remarked, ‘I wish I could have undergone similar training’. I conveyed this to the Principal Sri Hari Sinha. Such a compliment to the institution pleased him greatly and he showed it to the Member Engineering . I came to know of it through a subsequent letter to me by Sri Hari Sinha.

Our probation period of one and a half year was about to come to an end. As a part of the training all the probationers allotted to S.E.Rly were asked to prepare a project report on laying of a siding from Kanhan (near Nagpur) station to Kamptee colliery.

The task included survey, drawings, estimate and preparation of the project report. For this purpose we had to stay in the railway rest house at Nagpur station for about a week. This period was too inadequate for our assignment. We were not satisfied with the output. But our controlling officer cleared the report. On completion of the probation period we were to undergo departmental examination and interview by a committee of three HODs at the headquarters office. On satisfactory performance we got our first posting.